-

16A, Ijaiye road, Ogba

Lagos -

+234 803 5777 577

info@tanphija.com

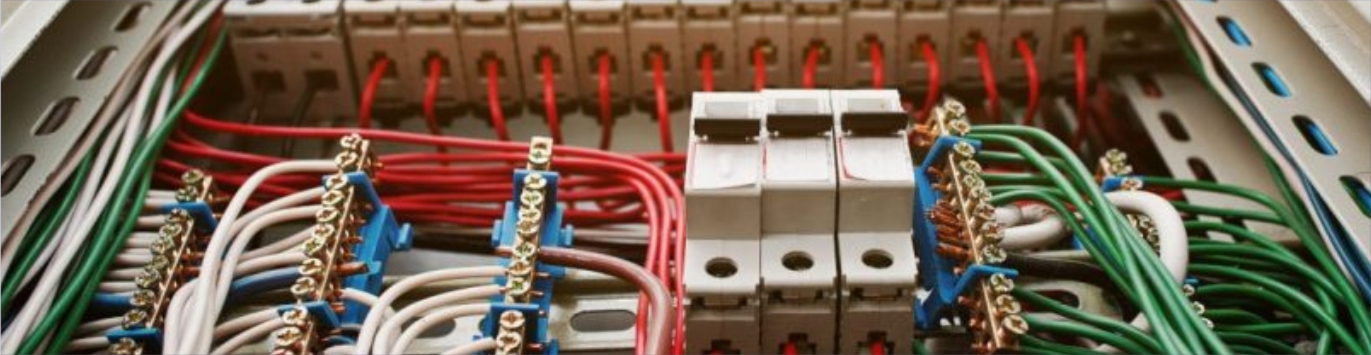

Control panels Tanphija distribution board comprises of component of an electrical supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure An electrical control panel is a special type of panel that houses electrical control systems and equipment. It is a dedicated enclosure designed to protect electrical components from dust, moisture, heat, and other environmental hazards. Our control panels is widely used in industrial, commercial, and residential applications, providing safety and convenience to users. Tanphija control panels are typically metal boxes with a locked door that protects the components from the environment, we provides safety and reliable way to control and monitor the electrical system.

The control panel can can also be programmed to perform certain tasks, such as turning on lights or controlling machines. This helps to reduce energy consumption and improve efficiency, help reduce the risk of electrical fires and other hazards. It is also relatively easy to install and maintain, making it a great choice for many applications. Industrial equipment and machines require defined functions and orderly control to achieve their various process goals. Electrical control panels carry out these functions within manufacturing equipment. An understanding of what they are highlights their critical importance to industry.

The structure of an electrical control panel is a combination of an enclosure and a back panel, similar to a breaker box in a home or office.

ENCLOSURES

The enclosure is a metal box which varies in size and is typically made of galvanize or stainless steel. The number of doors (usually one or two) needed on the enclosure determines its size in most industrial applications. The enclosure will come with a UL safety rating (508A is typical) an IP rating, and/or a NEMA classification. These listings help users determine properties such as:

• Indoor/outdoor use

• Waterproof/water resistance

• Dust/solid contaminants proofing

• Hazardous conditions rating

• Explosion-proof rating

These various classifications should be printed on a metal plate and attached to the enclosure for easy identification and reference.

Recirculation ductwork designs provide precise airflow to specific areas of the product resulting in smaller foot print ovens thus reducing utility and factory space costs.

High-efficiency electric heat sources to reduce energy costs.

Robust structural oven frames and component supports.

specific insulation materials are selected to provide optimum insulating characteristics and long term energy

savings.